20

Feb

Hydraulic bolt tensioning:

Table of Contents

- Hydraulic Bolt Tensioning: Enhancing Efficiency and Safety

- The Advantages of Hydraulic Bolt Tensioning

- Applications of Hydraulic Bolt Tensioning

- Key Considerations for Hydraulic Bolt Tensioning

- Summary

Hydraulic Bolt Tensioning: Enhancing Efficiency and Safety

Hydraulic bolt tensioning is a powerful technique used in various industries to achieve accurate and uniform bolt loading. This method utilizes hydraulic power packs to apply tension to bolts, ensuring optimal performance and safety. In this article, we will explore the benefits, applications, and key considerations of hydraulic bolt tensioning.The Advantages of Hydraulic Bolt Tensioning

Hydraulic bolt tensioning offers several advantages over traditional bolt tightening methods. Let’s delve into some of the key benefits:- Uniform Bolt Loading: Hydraulic bolt tensioning ensures uniform and controlled bolt loading, minimizing the risk of uneven stress distribution. This leads to improved joint integrity and reduced chances of leakage or failure.

- Time and Cost Savings: Compared to manual bolt tightening, hydraulic tensioning significantly reduces the time required for the task. The use of hydraulic power packs allows for faster and more efficient bolt tensioning, resulting in cost savings for industries.

- Enhanced Safety: Hydraulic bolt tensioning eliminates the need for impact wrenches or torque wrenches, reducing the risk of operator injuries. The controlled application of tension also minimizes the chances of bolt failure during operation, enhancing overall safety.

- Increased Accuracy: Hydraulic tensioning tools provide precise control over the applied load, ensuring accurate bolt tensioning. This accuracy is crucial in critical applications where precise bolt loading is necessary for optimal performance.

Applications of Hydraulic Bolt Tensioning

Hydraulic bolt tensioning finds applications in various industries where secure and reliable bolted connections are essential. Some notable applications include:- Oil and Gas: In the oil and gas industry, hydraulic bolt tensioning is widely used for flange connections in pipelines, valves, and pressure vessels. The technique ensures leak-free joints and prevents costly downtime.

- Power Generation: Hydraulic bolt tensioning plays a crucial role in power generation facilities, where large turbines and generators require precise and reliable bolted connections. The technique helps maintain the integrity of these critical components.

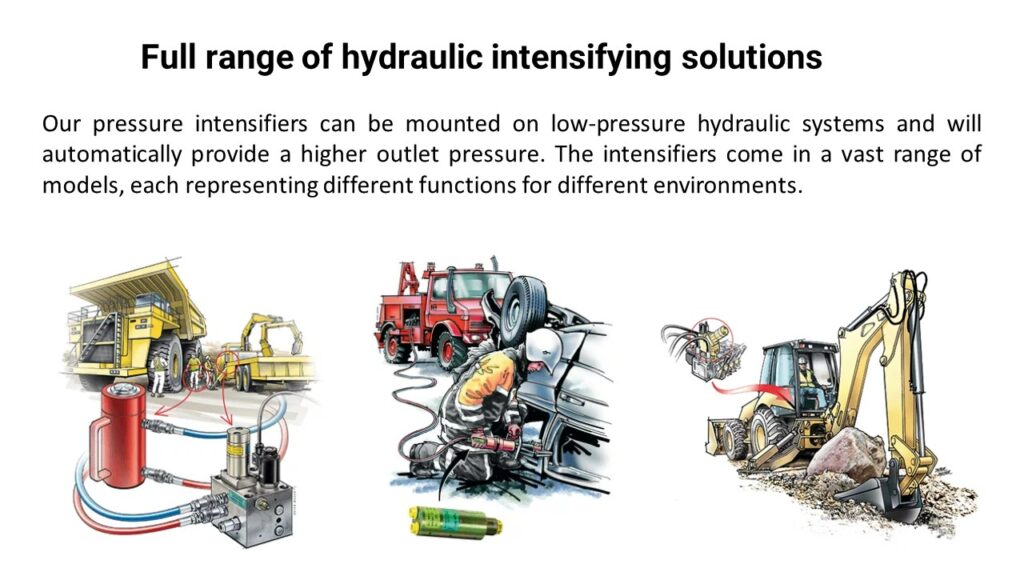

- Heavy Machinery: Industries involving heavy machinery, such as mining and construction, rely on hydraulic bolt tensioning to secure critical components like engine blocks, gearboxes, and structural connections. This ensures the safe and efficient operation of machinery.

- Transportation: Hydraulic bolt tensioning is also utilized in the transportation sector, particularly in the assembly of railway tracks, bridges, and aircraft structures. The technique ensures the structural integrity and safety of these vital transportation systems.

Key Considerations for Hydraulic Bolt Tensioning

While hydraulic bolt tensioning offers numerous benefits, it is essential to consider certain factors to ensure successful implementation:- Proper Training: Operators must receive adequate training to understand the correct usage of hydraulic tensioning tools and power packs. This helps prevent accidents and ensures optimal results.

- Accurate Bolt Specifications: It is crucial to have accurate information about the required bolt specifications, including size, material, and torque requirements. This ensures the selection of appropriate hydraulic tensioning tools.

- Regular Maintenance: Hydraulic tensioning tools and power packs should undergo regular maintenance to ensure their optimal performance and longevity. This includes inspections, lubrication, and replacement of worn-out components.

Summary

Hydraulic bolt tensioning is a powerful technique that offers numerous advantages in terms of uniform bolt loading, time and cost savings, enhanced safety, and increased accuracy. Its applications span across industries such as oil and gas, power generation, heavy machinery, and transportation. However, proper training, accurate bolt specifications, and regular maintenance are crucial considerations for successful implementation. By harnessing the power of hydraulic bolt tensioning, industries can achieve secure and reliable bolted connections, leading to improved efficiency and safety in their operations.

In-House remanufactured Carrier compressors

When it comes to air conditioning systems, Carrier is a name that stands out. Known for their high-quality products....

Revolutionizing Diesel Purification with Waagene Purifiner Technology

Diesel fuel quality is paramount for the efficient operation of engines...