MiniBOOSTER Hydraulic Intensifier HC7-10.3-G

- Payment by invoice possible

- Not currently in stock, contact us for factory lead times

- Payment by invoice possible

- In stock at factory, ready to ship in estimated 1-2 weeks, contact us for expedited options

- Del Rey is proud to be the exclusive distributor of Waagene products

- Payment by invoice possible

- Low quantities typically kept on hand; please contact us for availability at lead time

- Authorized MiniBOOSTER distributor & hydraulic excellence partner

Product Description

The HC7 – 10.3 – G is a remarkably compact high-pressure unit, weighing just 1.5 kg yet capable of delivering pressures of up to 2,000 bar. Designed for portable applications such as power packs, it efficiently elevates supplied pressure to a higher outlet pressure while automatically adjusting for oil consumption to sustain the desired high pressure. Outlet pressure adjustment is achieved by modifying the supplied pressure. With adaptable high-pressure adapters, various thread types can be accommodated, starting from the M22x1.5 thread in the HP port. Higher pressure options are also available upon request.

Additional information

Product Specifications

- HC7 versions: 10 different intensification factors

- PIN: 20 – 207 bar

- PH: 2,000 bar maximum

- PRETURN: As low as possible (return pressure to tank)

- POUTLET: PH = (PIN – PRETURN) x intensification factor

- Mounting: Inline tube

- Weight: 1.5 kg

Model Versions:

- A model = no dump valve

- B model = with dump valve

- B model = direct proportionally controlled

Material certificate 3.1 on request

Flow Rate

| i (Intensification factor) | Max. intensified outlet flow (l/min) | Max. inlet flow (l/min) |

|---|---|---|

| 4.0 | 2.0 | 14.0 |

| 5.0 | 1.6 | 14.0 |

| 6.6 | 1.3 | 13.0 |

| 7.6 | 1.1 | 13.0 |

| 9.0 | 0.9 | 13.0 |

| 10.3 | 0.8 | 12.0 |

| 13.0 | 0.6 | 12.0 |

| 16.0 | 0.5 | 12.0 |

| 20.0 | 0.3 | 12.0 |

| 25.0 | 0.2 | 12.0 |

Functions Desctiption

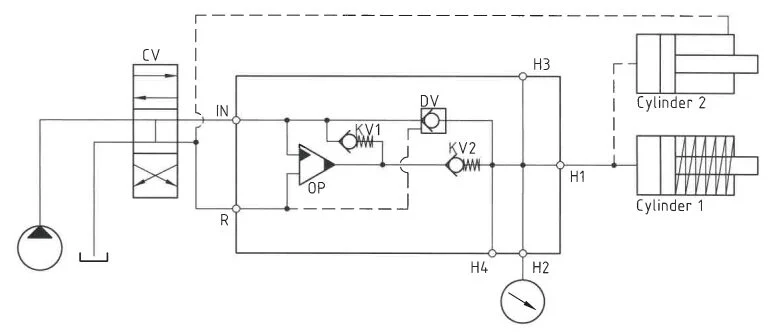

This system utilizes a directional valve (CV) to regulate the flow of oil, allowing it to pass through check valves (KV1, KV2, and DV) to reach the high-pressure side (H). Initially, maximum flow through the booster is attained for rapid forward motion. Once pump pressure is attained on the high-pressure side, the valves (KV1, KV2, and DV) close. The oscillating pump unit (OP) then maintains the end pressure automatically, stalling when the desired pressure is reached. Should there be a pressure drop due to consumption or leakage, the OP valve adjusts accordingly to uphold the end pressure.

Function Diagram

Dimensions

Connection Types

| Connection | IN / R | H |

|---|---|---|

| 1 | 1/4″ BSPP | M22 x 1.5 |

| 2 | 7/16-20″ UNF | M22 x 1.5 |

High-pressure adapters

Ordering an HC7

Ordering example of an HC7 with i = 13.0, H1 M22 x 1.5 and H2 9/16-18 UNF, DV incorporated and BSPP connections: HC7 – 13.0 – B – 12

Attention note!

High-pressure adapter is required, please specify ordering code – see high-pressure adapter table.

High-pressure adapters will be factory mounted.

The G-model is available in 2 variants, when ordering please specify accordingly:

- Dynamic – low hysteresis: Ordering example of an HC7 with i = 13.0 RV incorporated, H1 M22 x 1.5 and H2 9/16-18 UNF and BSPP connections: HC7 – 13.0 – G – 12.

- Fail safe – high hysteresis: The RV valve opening ratio is to be determined on individual basis. Contact our technical support. Ordering example of an HC7 with i = 13.0 RV with opening ratio x.x incorporated, H1 M22 x 1.5 and H2 9/16-18 UNF and BSPP connections: HC7 – 13.0 – G – x.x – 12 .

Model

- HC7

Intensification,i

- Select factor

- See flow rate table

Model Version.

- Select type

- A = without DV

- B = with DV

- G = with proportional valve

Connections.

- Select thread

- See table below

| Ordering code | IN / R | H1 | H2 | H3 | H4 |

|---|---|---|---|---|---|

| HC7-___-__-11 | 1/4″ BSPP | M22 x 1.5 | – | – | – |

| HC7-___-__-21 | 7/16-20 UNF | M22 x 1.5 | – | – | – |

| HC7-___-__-12 | 1/4″ BSPP | M22 x 1.5 | 9/16-18 UNF | – | – |

| HC7-___-__-22 | 7/16-20 UNF | M22 x 1.5 | 9/16-18 UNF | – | – |

| HC7-___-__-13 | 1/4″ BSPP | M22 x 1.5 | 9/16-18 UNF | 9/16-18 UNF | – |

| HC7-___-__-23 | 7/16-20 UNF | M22 x 1.5 | 9/16-18 UNF | 9/16-18 UNF | – |

| HC7-___-__-14 | 1/4″ BSPP | M22 x 1.5 | 9/16-18 UNF | 9/16-18 UNF | 9/16-18 UNF |

| HC7-___-__-24 | 7/16-20 UNF | M22 x 1.5 | 9/16-18 UNF | 9/16-18 UNF | 9/16-18 UNF |

Max. Tightening Torque BSPP

| IN / R | |

| 1/4″ BSPP | |

| with steel washer | 4.0 da/Nm |

| with cutting edge | 4.0 da/Nm |

Max. tightening torque flange mounting

| 7/16-20″UNF | ||

| With O-ring | 2.0 da/Nm |

Related Products

- List Item #1

- List Item #2

- List Item #3