MiniBOOSTER Hydraulic Intensifier HC62-013-1.2-A-1

- Payment by invoice possible

- Not currently in stock, contact us for factory lead times

- Payment by invoice possible

- In stock at factory, ready to ship in estimated 1-2 weeks, contact us for expedited options

- Del Rey is proud to be the exclusive distributor of iLumiGlo products

- Del Rey is proud to be the exclusive distributor of Waagene products

- Payment by invoice possible

- Low quantities typically kept on hand; please contact us for availability at lead time

- Authorized MiniBOOSTER distributor & hydraulic excellence partner

Product Description

HC62 – 013 – 1.2 – A – 1 In-line Intensifier System is designed to boost the hydraulic pressure from the pump to the workload. It operates only when needed, to save energy. The system is dynamical by means of being able to provide flow at high pressure.

Typical applications

Mobile attachments; motors – steering systems – cutters – crushers – shears, off highway equipment, injection molding machines and hydraulic presses. Applicable to machines with insufficient pump capacity to prevent machine stoppage when peak pressures occur.

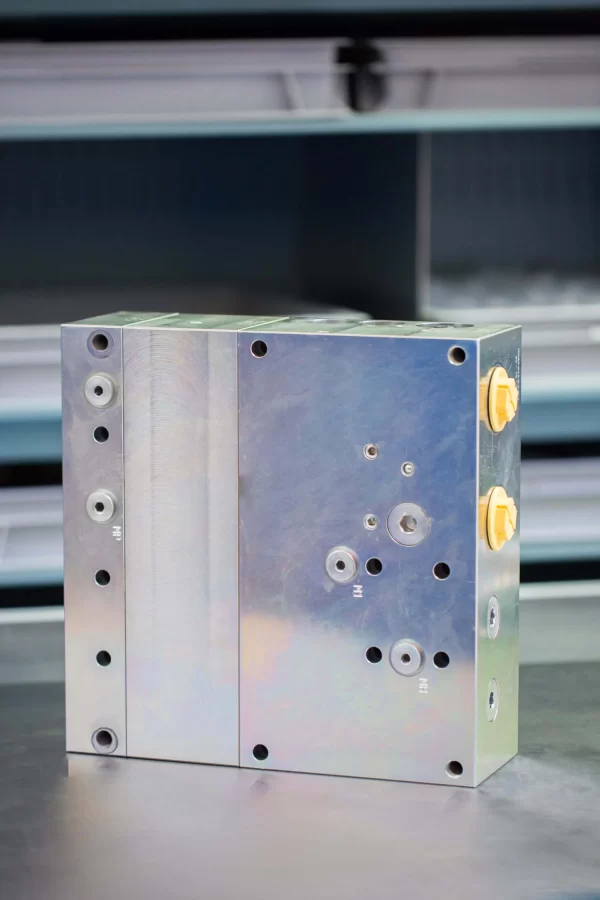

Easy installation

HC62 – 013 – 1.2 – A – 1 is provided with four mounting holes for through bolt installation. The four connection ports are placed logically in pairs and in line of each other on the HIC block. All surfaces are electroplated for good protection and fine surface finish.

HP flange mounting is optional. Furthermore, it is possible to flange multiple HC62-013 intensifier systems in order to achieve higher flow.

Additional information

Product Specifications

- Automatically activated (sequence valve)

- High pressure – up to 800 bar (11,600 psi)

- Fast fill – system flows up to 300 l/min

- Max. inlet pressure = 345 bar

- Adjustable outlet pressure

- Extended service life

- Robust design

- Flexible design; several boosters/intensification ratios

- Switch from by-pass to intensified flow

- Mounting: Inline tube or flanged

- Weight: 48.0 kg/ 105.8 lbs.

Model Versions:

- A model = no dump valve

- B model = with dump valve

- G model = direct proportionally controlled

Material certificate 1.2 on request

Flow Rate

| Intensification factor (i) | Max. intensified outlet flow l/min |

Max. by-pass pump flow l/min |

|---|---|---|

| 1.2 | 43.0 | 300 |

| 1.5 | 37.0 | 300 |

| 2.0 | 32.0 | 300 |

| 2.5 | 26.0 | 300 |

| 3.3 | 22.0 | 300 |

| 4.0 | 18.0 | 300 |

| 4.9 | 14.0 | 300 |

| 6.3 | 11.0 | 300 |

| 8.2 | 9.0 | 300 |

Functions Description

The function of the system is simple, but smart. The hydraulic oil is by-passed directly from the pump to the workload at maximum flow when back pressure from the workload has reached a set point close to the maximum pressure of pump.

A sequence valve opens and directs the oil to the booster, which makes the pressure rise. The shift between maximum pump pressure and high pressure happens without intervention from the user and ensures that the workload at all times will be driven at a maximum speed in relation to the required high pressure.

A relief valve is installed to control the maximum allowable pressure the system can output, allowing the booster to go for a higher end pressure producing flow at the decided pressure.

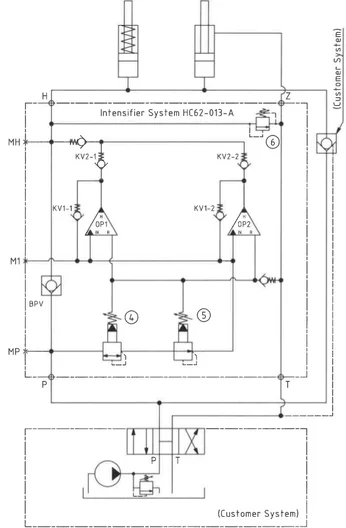

Function Diagram

Function Diagram HC62-013-1.2-A-1

Dimensions

Dimensions Diagram HC62-013-1.2-A-1

Connection Types

| Connection | P / T / Z | H | |

|---|---|---|---|

| 1 | 1″ BSPP | 1″ BSPP | |

| 1 | 1″ BSPP |

|

Flange mounting

Dynamic seals

| Code | Seal material media 1 / 2 | Outlet pressure |

|---|---|---|

| HH | H-PUR / H-PUR | Max 1,380 bar HP |

| HP | H-PUR / PEEK | Max 1,380 bar HP |

| EE | EPDM / EPDM | Max 500 bar HP |

| EP | EPDM / PEEK | Max 1,380 bar HP |

Ordering an HC62-013

Ordering example of an HC62-013 with i = 1.2, DV incorporated and BSPP connections: HC62 – 013 – 1.2 – A – 1

Attention note!

The G-model is available in 2 variants, when ordering please specify accordingly:

- Dynamic – low hysteresis: Ordering example of an HC62-013 with i = 1.2 RV incorporated and BSPP connections: HC62-013 – 1.2 – A – 1

- Fail safe – high hysteresis: The RV valve opening ratio is to be determined on individual basis. Contact our technical support. Ordering example of an HC62-013 with i = 1.2 RV with opening ratio x.x incorporated and BSPP connections: HC62-013 – 1.2 – A – x.x – 1

Model

- HC62-013

Intensification,i

- Select factor

- See flow rate table

Model Version.

- Select type

- A = without DV

- B = with DV

- G = with proportional valve

Connections.

- Select thread

- 1 = BSPP

Dynamic seals

- Select seal type

- See dynamic seal table

Selection of intensification factor

The intensification factor depends on available inlet and desired outlet pressure. To calculate the initial factor, please use the following formular:

i = Desired high pressure / Pump pressure

Desired pressure: 500 bar

Pump pressure: 200 bar

i = 500 / 200 = 2.5

For static use: Select an intensification factor higher or equal to the calculated value. In this case i = 2.5, the desired pressure of 500 bar is finally adjusted with the HP relief valve.

For dynamic use: Select an intensification factor 60% higher than the calculated value. In this case i = 500 / 200 = 2.5 + 60% = 4.0, the desired pressure of 500 bar is finally adjusted with the HP relief valve.

Adjust the pressure-reducing valve to reach a pressure 40% higher than the settings at the relief valve. In this case 500 + 40% = 700 bar.

Max. tightening torque

| P/T | H/Z | ||

|---|---|---|---|

| 1″ BSPP | 1″ BSPP | 1/8″ BSPP | |

| With stainless steel washer | 33.0 da/Nm | 33.0 da/Nm | 2.0 da/Nm |

| With stainless steel washer | 33.0 da/Nm | 33.0 da/Nm | 2.0 da/Nm |

Max. tightening torque flange mounting

| mounting bolt | |

|---|---|

| M10 8.8 | 5.0 da/Nm |